Title: The Production Process of Duck Feather Blankets

The production process of duck feather blankets is a complex and meticulous task that requires a series of steps to ensure the quality and warmth of the final product. Firstly, ducks are selected and their feathers carefully plucked to obtain the necessary raw material. The feathers are then cleaned and processed to remove impurities and make them suitable for use in the blanket.Next, the processed feathers are spun into yarn, which is then woven into a fabric that forms the base of the blanket. This fabric is then cut into the desired shape and size of the blanket, taking into account the specific needs of the customer. The cut pieces are then sewn together to form the final blanket, which is then inspected for quality and warmth before being packaged and shipped to the customer.Throughout the production process, strict attention is paid to hygiene and quality control to ensure that each blanket is safe and comfortable for the user. The process also involves numerous tests to ensure that the blankets meet the required standards of quality and performance. In conclusion, the production of duck feather blankets is a highly skilled and specialized task that requires great care and attention to detail.

Abstract:

The production of duck feather blankets involves multiple steps and processes to ensure the final product is of high quality and meets consumer demands. From the selection of raw materials to the final packaging, each step requires precision and attention to detail. This article outlines the production process of duck feather blankets, emphasizing the importance of each step and providing a comprehensive understanding of how these products are made.

I. Introduction

Duck feather blankets have long been a popular choice for winter warmth, offering a soft, cozy layer of protection against the cold. The process of making these blankets, however, is not as simple as it may seem. From the selection of the finest duck feathers to the final stitching together, each step requires meticulous care and attention to ensure the end product is not just warm but also comfortable and durable.

II. Raw Material Selection

The first step in the production of duck feather blankets is the selection of raw materials. This includes both the duck feathers and the fabric that will be used to stitch them together. The quality of these raw materials will directly affect the end product, so it is crucial to choose the best ones available.

Duck feathers are selected based on their length, strength, and elasticity. The longer and stronger the feather, the better it will retain heat and provide insulation. The elasticity of the feather also affects its performance, as it allows the blanket to conform to the body more easily and reduce heat loss.

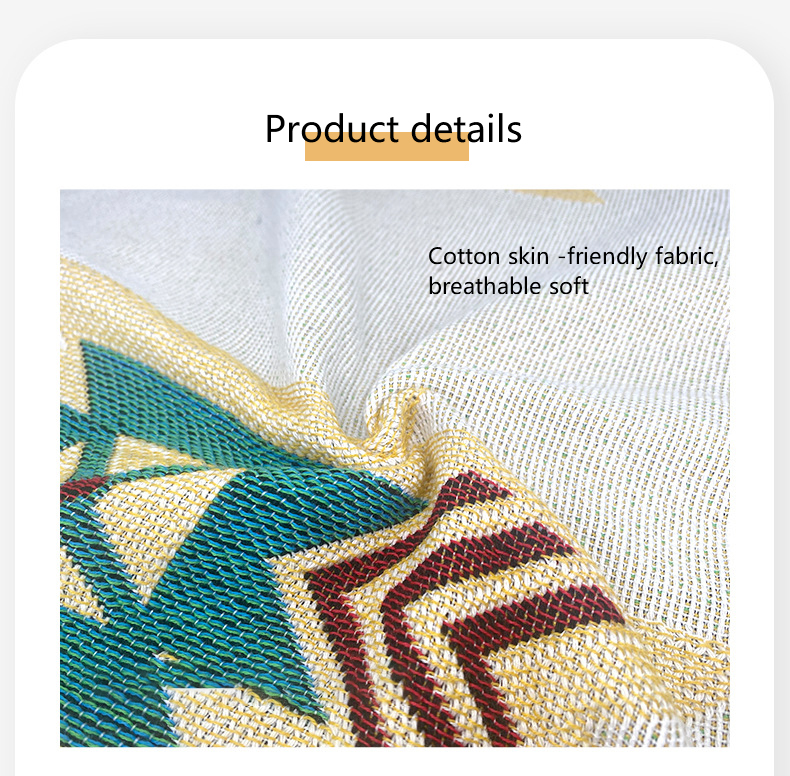

The fabric used to stitch the feathers together is also important. It needs to be strong enough to hold the feathers in place but also soft enough to provide comfort against the skin. Additionally, it should have good breathability to prevent heat build-up and discomfort.

III. Feather Processing

Once the raw materials are selected, the next step is to process the duck feathers. This involves cleaning and drying the feathers to remove any impurities or moisture that may be present. The cleaning process may involve water washing or干洗 methods, depending on the specific production process. The drying step is crucial as it helps to retain the natural oils and proteins in the feather, which are essential for its insulating properties.

IV. Blanket Assembly

Once the feathers are processed, they are then used to assemble the blanket. This involves taking a piece of fabric and stitching the processed feathers onto it in a specific pattern or design. The stitching process should be done carefully to ensure that the feathers are evenly distributed and provide maximum coverage and warmth. The pattern or design can vary depending on the manufacturer’s preference or customer demand.

V. Quality Control & Testing

After the blanket is assembled, it undergoes quality control and testing to ensure its quality and performance meet specified standards or requirements. This may involve measuring its thickness, weight, and other physical properties to ensure they fall within acceptable ranges. Additionally, testing may also include assessments of its thermal performance, such as how well it retains heat or how quickly it warms up when used.

VI. Packaging & Distribution

Finally, once a blanket has passed all quality control tests, it is packaged for distribution to customers or retailers. The packaging material should protect the blanket from moisture or other environmental factors that could affect its performance or appearance negatively during storage or transportation. Additionally, packaging also provides a convenient way for customers to carry or store their blankets when not in use.

VII. Conclusion

The production process of duck feather blankets is complex but ensures a high-quality product is delivered to customers each time they purchase one of these cozy winter essentials . From selection of raw materials to final packaging & distribution , each step requires precision & attention to detail so that consumers can enjoy a warm & comfortable sleep even during colder weather months .

Articles related to the knowledge points of this article:

The Cost of Fabric Per Meter for Down Comforters

Quality Testing of Down Comforters: An Overview