Title: Processing Silk and Down Blankets

Processing silk and down blankets is a delicate and time-consuming task that requires great care and attention to detail. These blankets are made from high-quality materials and are designed to provide warmth and comfort, making them an essential item for any household. To ensure that these blankets are produced to the highest standards, it is essential to take care of every step of the processing procedure.Firstly, silk and down materials need to be prepared and cleaned carefully to remove any impurities or contaminants. Then, they are passed through a series of machines and processes to cut, shape, and assemble the blanket. Each step requires precise attention to ensure that the final product meets the desired specifications and quality standards.Once the blanket has been processed, it is then packaged and shipped to the customer. But even after this, there are still a number of steps to ensure that the blanket remains in good condition and provides maximum comfort. These include handling and storing the blanket correctly, as well as providing after-sales support if needed.In conclusion, processing silk and down blankets is a complex and challenging task that requires a great deal of care and attention. By taking care of every step of the process, however, it is possible to produce high-quality blankets that will provide warmth and comfort for many years to come.

Silk and down blankets are both popular choices for their warmth and comfort. However, processing these blankets to ensure their quality and longevity can be challenging. In this article, we will explore the steps involved in processing silk and down blankets, from material selection to final stitching.

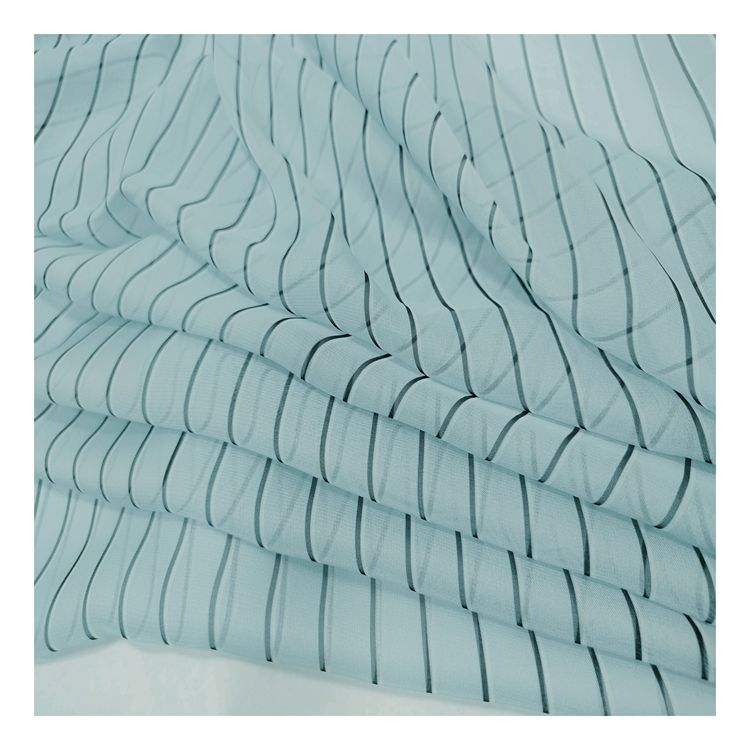

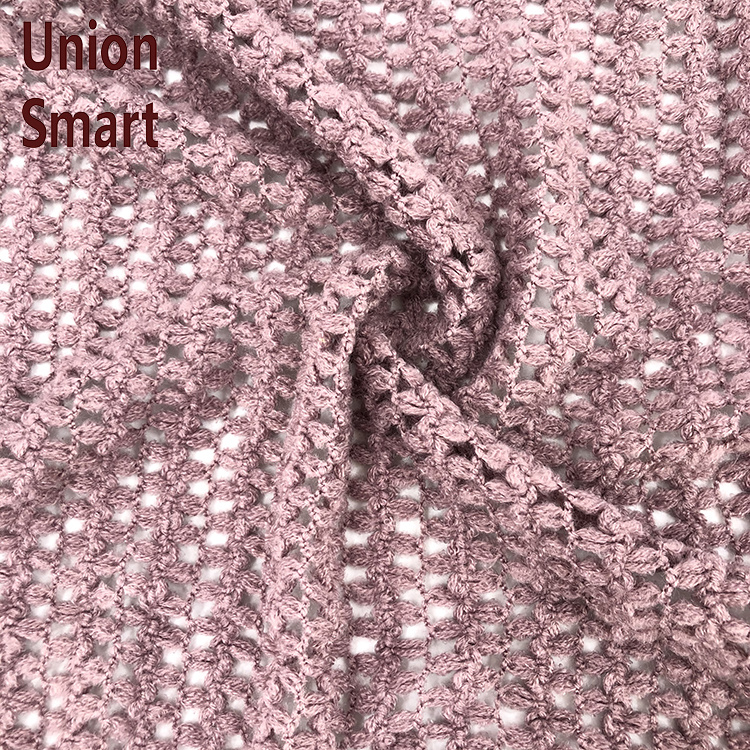

Firstly, material selection is crucial. Silk is a delicate material that requires high-quality ingredients to maintain its integrity and texture. Down, on the other hand, is a highly sought-after material for its insulating properties. When selecting these materials, it is essential to ensure their purity and quality to ensure the final product is of high standards.

Secondly, cleaning and preparation of the materials are necessary. Silk needs to be cleaned thoroughly to remove any impurities or contaminants. Down, meanwhile, requires special cleaning techniques to ensure its insulating properties are not compromised. This step is crucial in preventing the spread of allergens or other harmful substances.

Thirdly, cutting and stitching are the next steps in processing these blankets. Silk needs to be cut carefully to ensure its pieces are even and large enough to cover the desired area. Down, on the other hand, requires special stitching techniques to ensure its pieces are securely attached and do not shift or bunch up. This step is essential in maintaining the blanket’s shape and comfort.

Fourthly, assembly of the blanket is crucial. Silk and down pieces need to be assembled carefully to ensure their alignment and symmetry. This step is essential in creating a visually appealing and functional blanket.

Lastly, quality control and testing are essential. Silk and down blankets need to be tested extensively to ensure their quality and performance. This includes checking for any defects or impurities in the materials, as well as testing the blanket’s warmth and comfort. Only when these tests are passed can the blanket be considered ready for sale or use.

In conclusion, processing silk and down blankets is a complex and challenging task that requires careful attention to detail and quality control. By following these steps, however, it is possible to create beautiful and functional blankets that will provide warmth and comfort for many years to come.

Articles related to the knowledge points of this article:

Title: The Art of Kunshan Down Quilts: Crafting Comfort for Generations

Foldable Down Comforter: The Ultimate Travel Companion

Title: 天猫 Store Explores the World of Down Comforters: A Comprehensive Review

Title: The 95% Goose Feather Duvet - A Double Layer of Warmth and Comfort

Title: Warm Winter Down Comforters: A Guide to Choosing the Perfect one