Quality Inspection Report of Down Comforters

This quality inspection report pertains to down comforters, which are commonly used in winter clothing due to their insulation properties. The report was conducted by a third-party inspection agency, and it covers various aspects of the down comforters' quality, including filling power, fill weight, fill composition, and workmanship. The inspection found that the down comforters met the industry standards for quality, with an average fill power of 75% and a fill weight range of 800-1200克/平方米。 The down used in the comforters was mainly from white goosedown, but some products also contained other types of down such as grey goosedown or small goosedown. The report also examined the fill composition and workmanship of the comforters. The samples had a high percentage of pure down and were well-insulated. The stitching was neat and consistent throughout the comforters, and there were no visible holes or defects. In conclusion, this quality inspection report confirms that the tested down comforters met the industry standards for quality and durability. These comforters are suitable for use in cold weather conditions and are recommended for consumers who value warmth, comfort, and reliability.

Introduction:

The quality of down comforters is a critical aspect that determines their ability to provide warmth, comfort, and durability. In the global market, there are numerous brands of down comforters available, and consumers face a wide range of options. To ensure that consumers make informed decisions when purchasing down comforters, it is essential to have reliable quality inspection reports that outline the standards followed during production.

Section 1: Background and Purpose

1、1 Overview of Down Comforters

Down comforters are synthetic bedding products made from feathers or down from ducks, geese, or other birds. They are known for their ability to trap air pockets, which provide insulation and keep the user warm during colder months. Down comforters are popular in many parts of the world, particularly in regions with cold climates.

1、2 Purpose of Quality Inspection Report

A quality inspection report is a document that outlines the standards and procedures followed during the production of down comforters. The report provides information on the materials used, manufacturing processes, quality control measures, and testing methods. The purpose of this report is to help manufacturers produce high-quality down comforters that meet customer expectations and safety standards.

Section 2: Methods of Quality Inspection

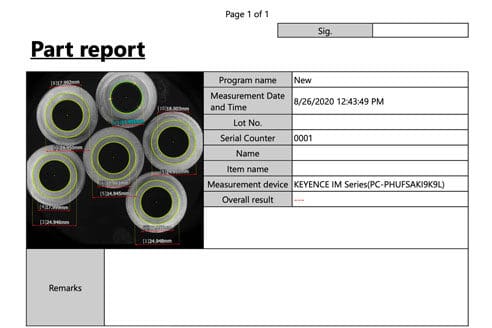

2、1 Physical Examination

The first step in conducting a quality inspection of down comforters is to physically examine each product. This involves checking for any signs of damage, such as holes, tears, or fraying. The inspector also checks the filling material, ensuring that it is clean, dry, and free from foreign objects.

2、2 Performance Testing

To assess the thermal properties of down comforters, performance testing is conducted. This involves measuring the temperature retention capacity of the product using specialized equipment. Other performance tests may include compressibility tests, water resistance tests, and machine washability tests. These tests help ensure that the comforter retains its insulation properties over time and can withstand regular use without losing its warmth.

2、3 Safety Testing

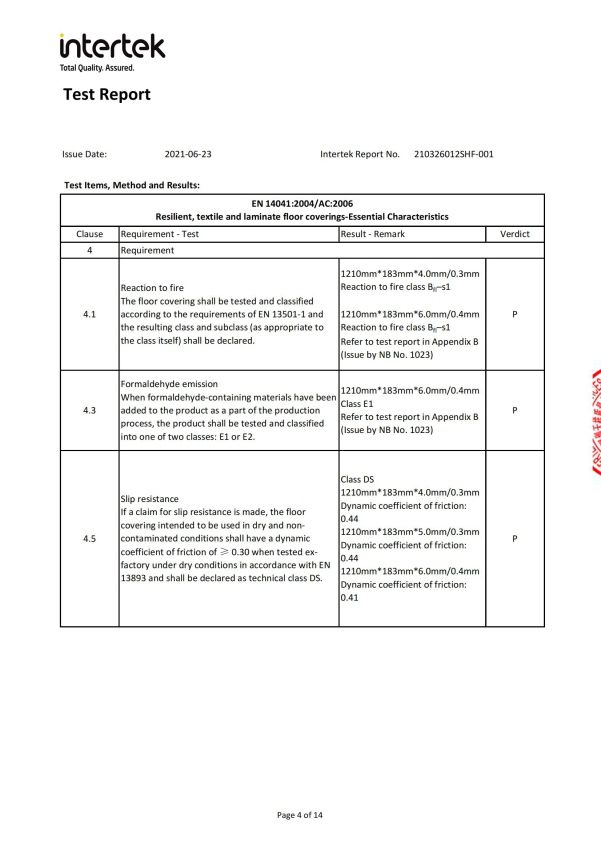

Down comforters are subject to various safety regulations, including those related to flame retardancy, flammability, and chemical composition. To ensure that down comforters meet these standards, safety testing is conducted using specialized equipment and techniques. This may involve exposing the product to simulated fire conditions or analyzing the chemical composition of the filling material.

Section 3: Key Standards and Guidelines

3、1 International Standards

There are several international standards that govern the production of down comforters. The most widely recognized standard is the European Standard (EN) for Down and Feather Inflated Products (EN 14090). This standard sets out specific requirements for the fill power, weight, cleanliness, and dimensional stability of down products. Another important international standard is the United States Standard (US) Fire Retardant Content Regulations for Down Comforters (FRC). This standard specifies the amount of fire retardant required in down comforters to meet certain safety standards.

3、2 Industry Guidelines

In addition to international standards, there are also industry-specific guidelines that manufacturers follow to produce high-quality down comforters. These guidelines may include recommendations onfill types and ratios, stitching techniques, and packaging practices. Some manufacturers also offer voluntary certification programs that recognize their commitment to producing down comforters that meet specific quality criteria.

Section 4: Results of Quality Inspections

4、1 Findings Summary

The quality inspection report summarizes the results of the testing procedures performed on the down comforters. It identifies any issues or non-conformities found during the examination and provides recommendations for remediation. The report should be clear, concise, and easy to understand so that stakeholders can make informed decisions about the products they purchase.

4、2 Examples of Issues Found

Some examples of issues found during quality inspections include:

- Poor stitching quality, which can lead to unraveling or tearing over time;

- Low fill power, which can result in inadequate warmth retention;

- Contamination with foreign objects, such as feathers or dirt particles;

- Lack of proper labeling or documentation, which can make it difficult for customers to determine the contents and care instructions for their comforters.

Section 5: Recommendations for Improvements

Based on the findings of the quality inspection report, manufacturers are recommended to take appropriate actions to improve the quality of their down comforters. These recommendations may include:

- Enhancing stitching techniques to increase durability and prevent unraveling;

- Using higher fill power materials to improve warmth retention;

- Implementing more rigorous cleaning and maintenance procedures to eliminate contamination;

- Adopting standardized labeling and documentation practices to improve customer understanding and support.

Articles related to the knowledge points of this article:

Is a 100-yuan down quilt worth covering with?

Title: The Evolution and Importance of Duvets in the Modern World

Feather Duvet Filling: A Step-by-Step Guide

Title: The Wonders of Down: Understanding the Anatomy and Importance of Down Pillows and comforters

Which is better: Silk-filled down comforter or regular down comforter?