Title: The Evolution of Down: Why There Are Duck Feather Duvets but No Chicken Ones

Title: The Evolution of Down: Why There Are Duck Feather Duvets but No Chicken OnesDown is a popular filling material for pillows and duvets due to its warmth, comfort, and lightweight properties. However, not all down is created equal, as different species of birds have varying levels of loft and durability. In this article, we will explore the evolution of down and why there are duck feather duvets but no chicken ones.The first down duvets were made from the feathers of geese and ducks, which had a higher loft and longer lifespan than other bird species. These duvets were expensive and considered a luxury item, but their warmth and comfort made them a popular choice among the wealthy. Over time, down duvets became more affordable, and their popularity grew.Today, there are several types of down available, including goose down, duck down, and synthetic down. Goose down is considered the highest quality, as it has the highest loft and longest lifespan. Duck down is less expensive but still provides good warmth and comfort. Synthetic down is a cheaper alternative that lacks the warmth and durability of natural down.In conclusion, the evolution of down has led to the development of various types of duvets that offer different levels of warmth, comfort, and durability. While there are chicken feather duvets available, they are not as popular or well-known as duck or goose feather duvets due to their lower loft and shorter lifespan.

Down has been a popular insulation material for centuries, providing warmth and comfort in sleeping bags, blankets, and duvets. However, the question of why there are duck feathers used in duvets but not chicken feathers remains unanswered. This article will delve into the history of down, its properties, and the reasons behind the preference for duck over chicken feathers in the production of duvets.

1. The Origins of Down: From Animal to Human Invention

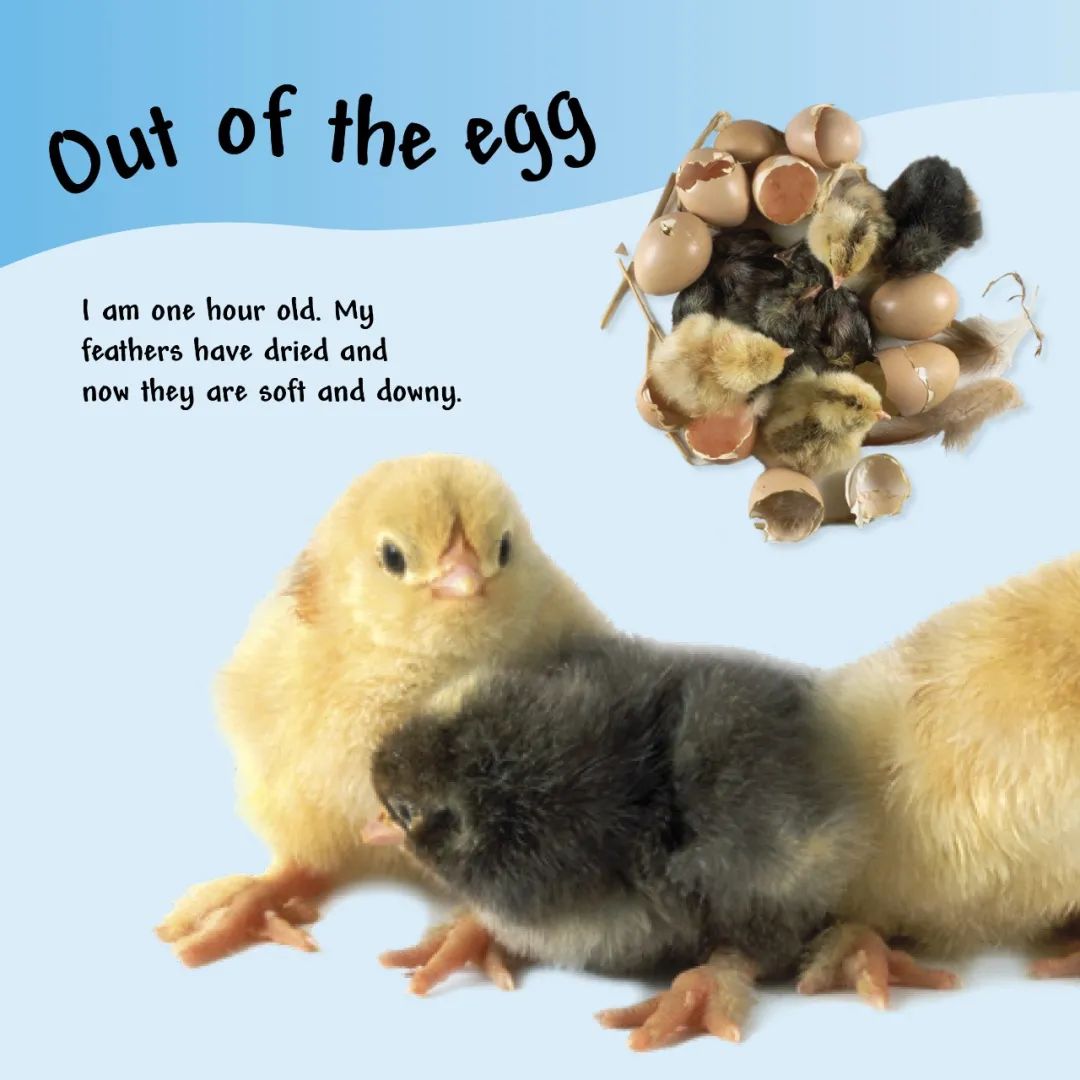

Duck down, or "downy" as it is commonly known, is the soft, fluffy undercoat found on the belly of ducks and waterfowl. For centuries, people have collected and exploited this natural resource for various purposes, such as insulation, clothing, and even medicinal remedies. In ancient China, for example, down was considered a precious gift from the heavens and was used to make quilts that kept people warm during the cold winter months.

The discovery of goose feathers as a suitable substitute for duck down can be traced back to medieval Europe. Goose feathers were lighter than duck feathers but lacked the insulating properties of down due to their smaller size and weaker structure. However, they were still useful in keeping people warm, especially in colder climates where duck feathers were not readily available. As trade routes expanded and cultures exchanged ideas, goose feathers became a popular choice for duvet filling throughout Europe and North America.

1. The Properties of Down: What Makes It So Special?

The unique properties of down make it an ideal insulation material for duvets. Here are some of the key factors that distinguish down from other materials:

a) Lightweight: Down is much lighter than most other types of insulation, which makes it easy to carry and use. A single feather can weigh less than a gram, while a standard duvet filling typically consists of several thousand feathers.

b) Insulating Power: Despite its light weight, down can trap air molecules more effectively than other insulation materials like wool or synthetic fibers. This makes it capable of maintaining a stable temperature within a duvet, even if the surrounding environment changes significantly.

c) Hypoallergenic: Some people may experience allergic reactions to feathers or other animal-derived materials. However, down is generally considered hypoallergenic because it does not contain irritants like mites or ticks that can cause skin irritation. Furthermore, modern duvet manufacturing processes have improved significantly in recent years, reducing the risk of contamination and increasing the overall safety and hygiene of down products.

d) Durability: While down fibers can be damaged by excessive moisture or heat exposure, they are relatively resilient and can withstand regular washing and use without losing their warmth or fluffiness. This durability makes down an attractive option for long-term use and frequent cleaning.

1. The Evolution of Duvet Manufacturing: From Handcrafted to Machine-Produced

The production of duvets has undergone significant changes over the centuries, from manual labor to machine-based automation. Here's a brief overview of the different methods used in duvet manufacturing:

a) Handcrafting: Traditionally, duvets were handmade with down collected from local flocks or purchased from specialized suppliers. The process involved cleaning and carding the feathers, stuffing them into a fabric casing, and sewing the casing closed securely. This method was labor-intensive and time-consuming but allowed for great flexibility in terms of design and customization.

b) Steaming: In the late 19th century, steam power emerged as a major technological advancement, leading to the development of steam-powered duvet machines. These machines used hot air to puff up the down fill and create a dense layer of insulation within the duvet casing. Steaming was faster than handcrafting but required a steady supply of heat and electricity to operate effectively.

c)机械化生产: In the early 20th century, mechanical devices began to replace human labor in duvet manufacturing. These devices relied on mechanical pins to push down feathers into a fabric casing, creating a more efficient and uniform fill. By the mid-20th century, fully automated duvet machines had become commonplace, allowing for mass production and lower costs. Today, most duvet manufacturers use advanced machinery that combines both manual intervention (such as sorting and trimming) and robotic automation (such as filling and sealing) to produce high-quality duvets at scale.

Articles related to the knowledge points of this article:

The Warmest Down Comforter: Its Final Destination

Title: Chongqing Down Duvet Wholesale Market Address

Can a Pregnant Woman Use a Duvet Made of Duck Feathers and Down at 11 Weeks?

Title: Explore the World of Down Blankets: A Comprehensive Collection of Down Quilt Images

The Art of Warmth: Exploring the Beauty and Comfort of Down Comforters