Title: The Unique Journey of Making Duvet in Wuhan

The journey of making Duvet in Wuhan is unique and interesting. Duvet, also known as the bedspread, is a crucial element of the bedroom decoration. It not only keeps the bed warm but also adds a touch of elegance to the entire room. The process of making Duvet in Wuhan involves several steps. Firstly, the raw materials are prepared, usually cotton or silk, which are then processed into thread. The thread is then woven into a fabric, often with a floral or geometric design. Once the fabric is ready, it is cut into the shape of Duvet and then sewn together. The final step is to add any embellishments or decorations to the Duvet, making it truly unique and special. The makers in Wuhan are skilled and experienced, and they take great care in creating each Duvet, ensuring that it meets the highest standards of quality and craftsmanship. From start to finish, the journey of making Duvet in Wuhan is a labor of love and precision, resulting in a beautiful and functional piece of bedroom furniture.

Wuhan, the capital of Hubei Province, is renowned for its diverse cultural heritage and modern urban landscape. However, did you know that Wuhan is also home to a thriving duvet-making industry? In this article, we explore the unique journey of making duvet in Wuhan, from the selection of raw materials to the final product.

The first step in making a duvet is to source the raw materials. The most common raw materials for duvet are duck and goose down, which are known for their excellent insulation and comfort properties. Wuhan is blessed with rich water resources, providing an abundant supply of ducks and geese. The down is collected from these birds during their molting season, when they naturally lose their old feathers and grow new ones.

Once the raw materials are sourced, the next step is to clean and process them. The down is washed thoroughly to remove any impurities or contaminants. Then, it is dried and processed to ensure its quality and performance. This process is crucial as it helps to maintain the integrity of the down and ensures that the final product is free from any harmful substances.

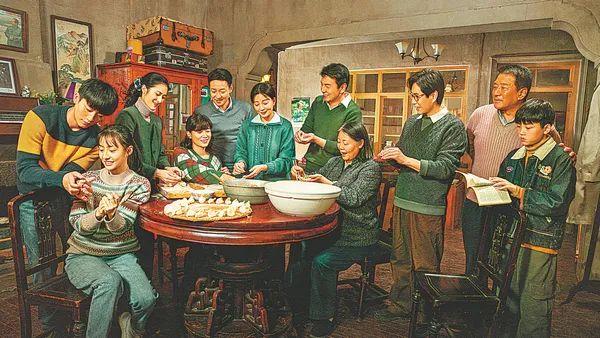

The next step is to assemble the components of the duvet. This includes stitching together the layers of down, adding a cover to protect the down from wear and tear, and attaching any necessary fillers or inserts to provide extra support or warmth. The duvet is then shaped and sized to fit standard bed frames.

Finally, the duvet undergoes quality control and testing to ensure that it meets all necessary standards and regulations. This includes checking for any defects or impurities in the down, testing its insulation and comfort properties, and ensuring that it is safe and hypoallergenic for use by consumers.

The journey of making a duvet in Wuhan is unique and requires a combination of traditional craftsmanship and modern technology. From sourcing the raw materials to undergoing quality control and testing, each step is crucial in ensuring that the final product is of high quality and meets the needs of consumers. Whether you are looking for a warm and cozy duvet to keep you cozy on cold nights or a lightweight summer duvet to keep you cool during hot summer days, Wuhan has got you covered!

Articles related to the knowledge points of this article:

Title: The Sniff of Down: Embracing the Charm of Down Comforters

Title: Dreamy Charm and Feathered Comfort: An Introduction to the Exquisite Mengxinyuan Down Quilt