Title: The Entire Process of Down Filling for Duck Down Comforters Video Playback

The entire process of down filling for duck down comforters involves several steps. First, the ducks are raised in a natural environment where they can roam freely and feed on insects and plants. This allows their feathers to develop into high-quality down feathers that are soft, warm, and lightweight. After the ducks have been raised, they are captured and transported to a processing center. Here, the feathers are cleaned and sorted by size and quality. The larger, more valuable feathers are selected for use in the comforter, while the smaller, less expensive ones are used forfill or padding. Next, the chosen feathers are cleaned once again to remove any remaining dirt or debris. They are then processed into a filling material that can be inserted into the comforter. This may involve stretching the feathers into thin strips or compressing them into small squares. Once the filling material is ready, it is inserted into the comforter shell using specialized machinery. The shell is then sewn together to create a complete comforter that will retain its shape and provide warmth and comfort to its user. Overall, the process of down filling for duck down comforters requires careful attention to detail and quality control in order to ensure that each comforter is both comfortable and durable.

Introduction:

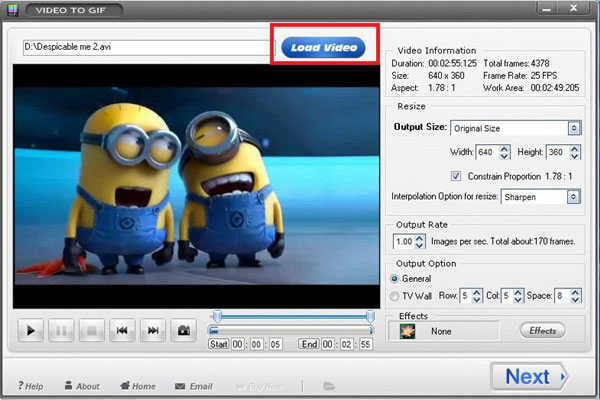

Down comforters are a type of bedding that is popular all over the world. They are known for their warmth, comfort, and durability. However, not many people know how down comforters are made. In this article, we will take a look at the entire process of down filling for duck down comforters through a video playback.

Body:

The process of making a duck down comforter starts with selecting the right ducks. The ducks used for filling must be at least 70% feather and 30% down. The ducks are usually selected from mature ducks that have been harvested at the right time. The feathers are then removed from the body of the duck and sold to manufacturers of down products.

Next, the down feathers are cleaned and sorted by size and quality. The larger and fluffier the feathers, the better they will blend together to create a soft and comfortable comforter. The down feathers are then dried in a special dryer that mimics the natural drying process of ducks. This helps to remove moisture and ensure that the down feathers maintain their loft and insulation properties.

After drying, the down feathers are combined with synthetic materials such as polypropylene fiber or microfiber fill. This combination helps to increase the durability and resilience of the comforter. The down and synthetic materials are then packaged into individual duvet covers or stuffed into duvet bags.

Finally, the completed comforters go through quality control checks to ensure that they meet industry standards. The comforters are then shipped to retailers and consumers all over the world.

Conclusion:

In conclusion, making a duck down comforter is a complex process that requires careful selection of ducks, cleaning and sorting of down feathers, blending with synthetic materials, packaging, and quality control checks. The end result is a warm, comfortable, and durable bedding product that will provide years of service to its owners. By watching the video playback of the entire process, you can gain a deeper understanding of how down comforters are made and appreciate the effort put into creating them.

Articles related to the knowledge points of this article:

Title: How to Deal with Down Pillows Lossing their Fluff?

The Cost of Customizing a Single Duvet with Down Feather

DIY Down Comforter: Cost Breakdown