Title: The Logistics of Down Comforters: Understanding the Supply Chain

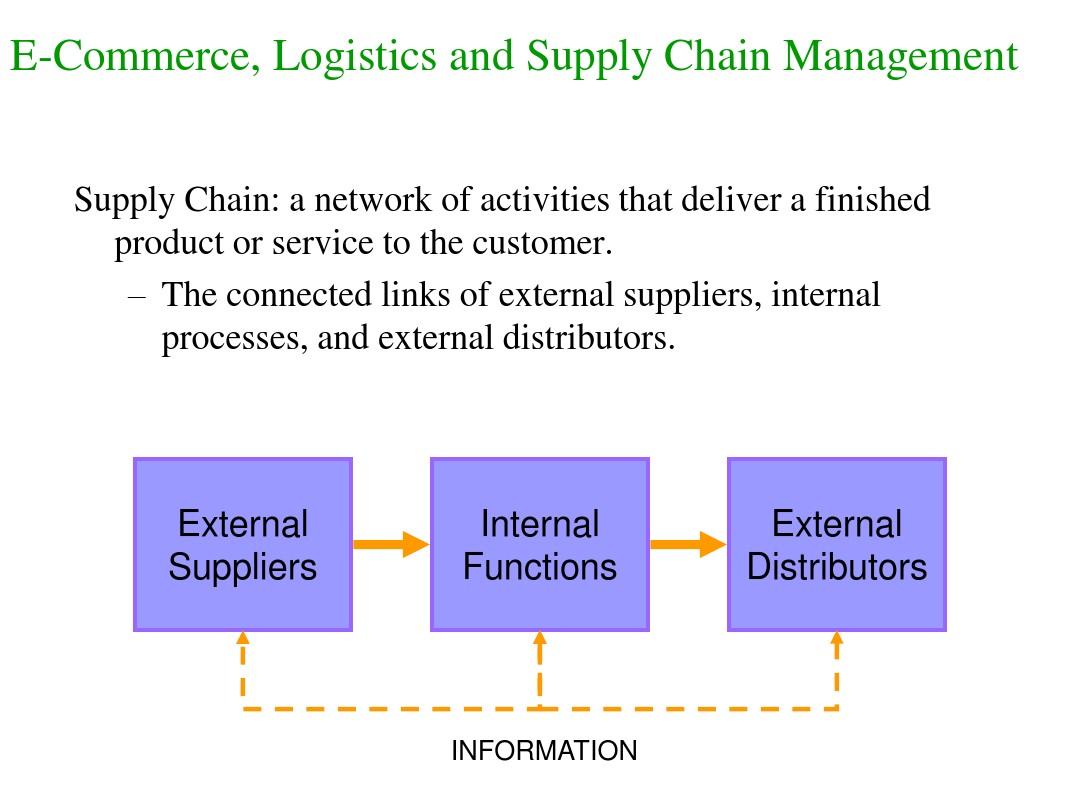

The production of down comforters involves a complex supply chain that starts with the harvesting of feathers from geese and ducks. The raw materials are then cleaned, processed, and transformed into insulation materials through various techniques such as washing, dedusting, and grading. These materials are then assembled into comforters through the addition of fillings, such as synthetic fibers or natural down. The final step is packaging and distribution to retailers and consumers. Despite the high demand for down comforters during cold weather seasons, the supply chain can be impacted by factors such as weather conditions, labor shortages, and price fluctuations. As a result, it is essential for manufacturers and suppliers to have efficient supply chain management strategies in place to ensure a stable and consistent supply of down comforters. In addition to the logistical challenges faced by the industry, there are also environmental concerns associated with the use of down feathers and their impact on the environment. Therefore, it is crucial for companies to adopt sustainable practices and promote the use of recycled materials in the production of down comforters. Overall, understanding the logistics of down comforters' supply chain is essential for both manufacturers and consumers to make informed decisions regarding their purchase and usage.

In the world of consumer goods, few products are as ubiquitous and essential as the down comforter. These lightweight and warm blankets have been a staple of indoor comfort for generations, providing respite from the cold winter months. However, behind each cozy blanket is a complex and intricate system of logistics and supply chain management that ensures its safe and timely delivery to consumers. In this article, we will delve into the world of down comforter logistics, exploring its origins, production process, distribution channels, and recent advancements in the industry.

The Origins and Production Process of Down Comforters

Down comforters are made from the feathers of certain bird species, particularly goose and duck. The birds are typically raised in cold climates and harvested when their feathers are at their heaviest, providing the best insulation properties. The down is then cleaned, processed, and sorted by size and quality before being spun into thread or weaved into fabric. The resulting comforter is then filled with synthetic filling materials such as foam or polyester to add weight and shape.

Logistics Management in Down Comforter Distribution

Once produced, down comforters must be distributed to retailers across the country or around the world. This involves a complex network of transportation, storage, and inventory control. Many companies opt for air freight, which offers faster delivery times but can be more costly. Others use ground freight or shipping containers, depending on the destination. Once the comforters arrive at their final destination, they are stored in warehouses until sold to consumers.

Challenges in Down Comforter Logistics

Despite the advances in technology and logistics management, there are still several challenges facing the down comforter industry. One major issue is waste management. Down comforters are highly durable and can last for many years, but when they reach the end of their lifespan, they often end up in landfills. To address this problem, some companies are beginning to adopt recycling programs for their discarded down comforters.

Another challenge is counterfeiting. With the rise of e-commerce, it has become increasingly difficult to distinguish between genuine down comforters and fake ones. To combat this problem, some companies have begun using blockchain technology to track the origin and authenticity of their products.

Recent Advancements in Down Comforter Logistics

As the demand for down comforters continues to grow, so too do the opportunities for innovation in logistics management. One promising development is the use of artificial intelligence (AI) to optimize supply chains. By analyzing data on weather patterns, sales trends, and customer preferences, AI algorithms can help businesses make more informed decisions about inventory levels, transportation routes, and pricing strategies.

Another area of growth is sustainable logistics. As consumers become more environmentally conscious, there is an increasing pressure to reduce the carbon footprint of the supply chain. Some companies are experimenting with alternative fuels for transportation, such as electric or hydrogen vehicles, or implementing circular economy practices such as rental models or product repurposing.

Conclusion

In conclusion, the logistics of down comforters is a complex and constantly evolving system that plays a critical role in ensuring consumer access to this essential item. From the careful selection of raw materials to the efficient distribution of finished products, every step in the process requires careful planning and execution. By understanding the logistics behind down comforters, we can gain insight into the broader issues surrounding global supply chain management and work towards more sustainable and efficient solutions.

Articles related to the knowledge points of this article:

How to Choose a Quality Home Textile Down Comforter

Title: Which is Better: Down or Goose: A Comprehensive Guide to Feathered Comfort

Title: The Hazards of Sleeping with Down Comforters: A Comprehensive Guide

Jinan District Feather Duvet Wholesale Prices

Title: Harmony Brand Down Comforter: The Ultimate Solution for a Comfortable Sleep Experience