Title: The Evolution of Fiberfill Down Quilts: From Polyester to Polyesterfill

Fiberfill down quilts have come a long way since their inception in the 1920s. Originally made of pure down feathers, they were known for their warmth and comfort. However, concerns about the health effects of down feathers led to the development of alternatives such as synthetic fibers and polyesterfill. These newer materials are still used today, but they offer some distinct advantages over traditional down. For example, polyesterfill is hypoallergenic and easier to clean than down. Additionally, it is more resistant to wear and tear. While there are some drawbacks to using polyesterfill, such as its lack of natural insulation properties, it has become a popular choice for many consumers due to its affordability and versatility. Overall, the evolution of fiberfill down quilts shows that innovation and technological advancements can help improve the functionality and sustainability of our sleeping products.

Introduction

As the temperature drops and winter approaches, many people look forward to snuggling up in their warmest blankets to keep themselves cozy and comfortable. One of the most popular types of bedding materials is a down quilt, which is known for its softness, warmth, and durability. However, not all down quilts are created equal. In this article, we will explore the evolution of fiberfill down quilts, from their early days as made of polyester fibers to the more recent use of polypropylene microfibers in filling. We will also examine the benefits and drawbacks of each type of filling material, and discuss how consumers can choose the right quilt for their needs.

Early Days of Down Quilts

The concept of using synthetic fibers to replicate the properties of natural down feathers dates back to the mid-20th century. At that time, polyester fibers were widely used in the production of down quilts due to their affordability and ease of processing. However, these synthetic fibers lacked the natural breathability and moisture-wicking properties of real down feathers. As a result, down quilts made from polyester often felt clammy and uncomfortable, especially during hot summer nights.

The Emergence of Polypropylene Microfibers

In response to consumer demand for more breathable and moisture-wicking down quilts, manufacturers began experimenting with alternative filling materials. One such material was polypropylene microfibers, which were derived from recycled plastic waste and had excellent heat retention properties. Unlike traditional polyester fibers, polypropylene microfibers could be spun into fine threads and woven into quilt covers and fillings with minimal loss of thermal efficiency. This made them ideal for use in cold weather bedding products.

The Benefits and Drawbacks of Polyester and Polypropylene Microfibers

When compared side by side, polyester and polypropylene microfibers have both their strengths and weaknesses. On one hand, polyester fibers are generally less expensive than polypropylene microfibers, making them more accessible to budget-conscious consumers. Additionally, polyester fibers are more durable than many other types of synthetic fibers, meaning they may last longer before needing replacement. However, polyester fibers lack the natural breathability and moisture-wicking properties of real down feathers, which can make them uncomfortable to sleep in on hot or humid nights.

On the other hand, polypropylene microfibers offer superior thermal efficiency compared to polyester, as they are able to retain more heat when exposed to cold air. This makes them an ideal choice for colder climates or for individuals who tend to overheat while sleeping. However, polypropylene microfibers are not as durable as polyester fibers and may require more frequent cleaning or replacement over time. Moreover, some consumers have raised concerns about the environmental impact of using synthetic fibers like polypropylene microfibers in bedding products.

Choosing the Right Down Quilt: Factors to Consider

When selecting a down quilt, there are several factors to consider beyond the type of filling material used. These include the fill power (the ratio of weight to volume), the level of craftsmanship and construction quality, and any additional features or technologies that improve comfort or functionality. For example, a high-fill power down quilt will provide greater warmth and durability over time than a lower-fill power product. Similarly, a well-constructed quilt with tight stitching and reinforced corners can help prevent leaks or damage caused by movement during sleep. Finally, some down quilts come with additional features like built-in pillows or duvet covers that can further enhance comfort and convenience.

Conclusion: The Future of Fiberfill Down Quilts

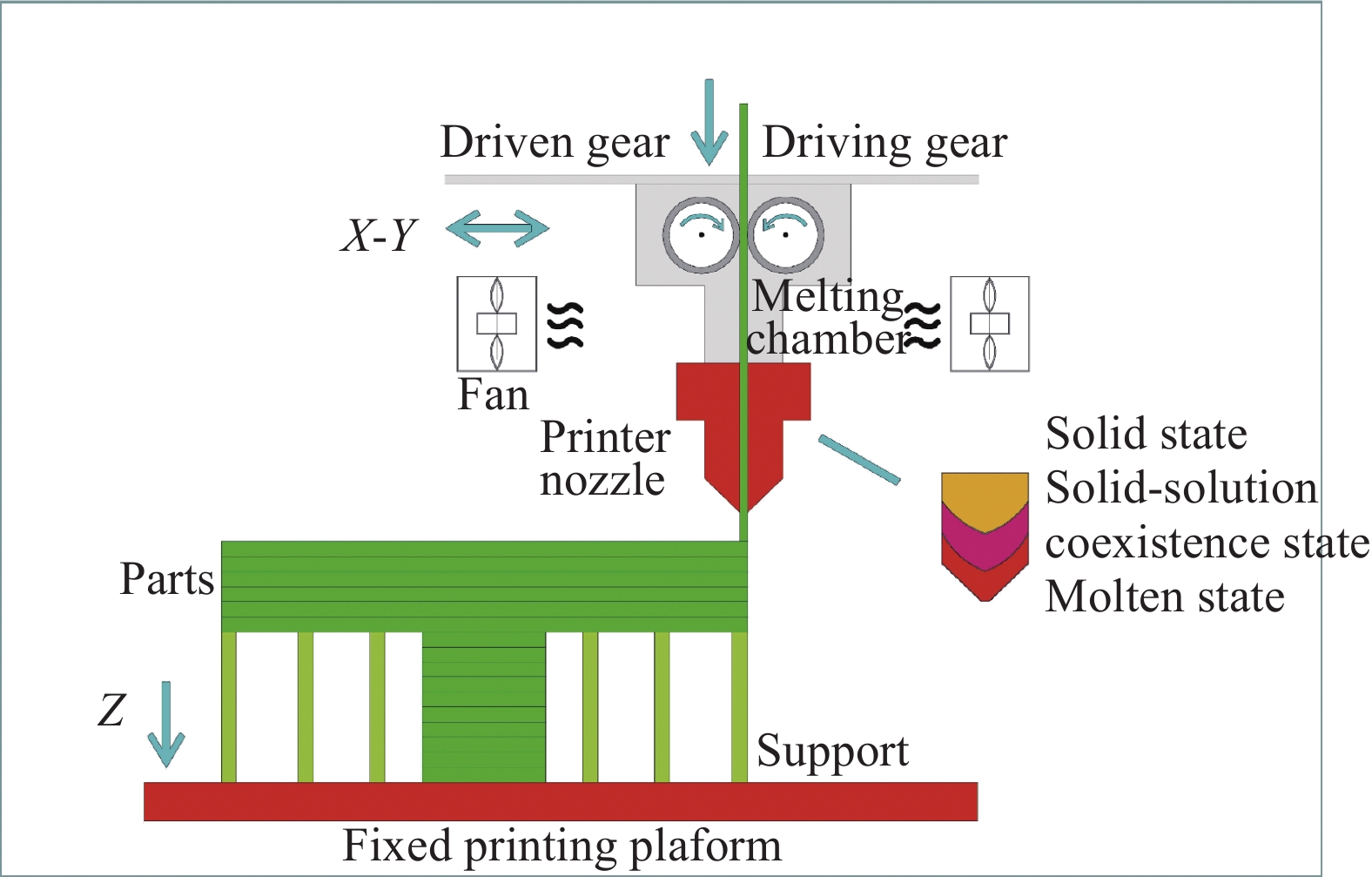

As consumers continue to demand more environmentally sustainable and technologically advanced bedding products, it is likely that we will see continued advancements in the design and production process of fiberfill down quilts. Whether it is through the use of new materials like biodegradable polymer fibers or cutting-edge manufacturing techniques like 3D printing, it is clear that the future of down quilts will be shaped by innovation and consumer demand. By staying informed about these trends and making thoughtful choices when purchasing down quilts, we can ensure that we stay warm and comfortable no matter how chilly our winter nights get.

Articles related to the knowledge points of this article:

The price of a 3 to 4-pound down blanket

How to Fluff Up a Down Comforter Video